Comparing solenoid and manual pneumatic valves reveals distinct advantages and disadvantages. Solenoid valves offer automation and remote control, enhancing efficiency and reducing the need for human intervention. They’re ideal for applications where precision timing and rapid response are critical. However, manual valves provide simplicity and reliability, making them cost-effective and suitable for basic operations. On the downside, manual valves lack the speed and precision of solenoid valves. The choice between them depends on the specific application’s requirements, automation needs, and budget considerations. It’s crucial to weigh the pros and cons when selecting the appropriate valve for any pneumatic system.

Automation vs. Manual Control: Solenoid Valve Overview

In the world of pneumatic systems, the choice between automation and manual control is a critical decision, often hinging on the type of valve used. Solenoid valves are a common choice for those seeking automation. These valves are electromechanically operated and provide precise control over the flow of air or other gases within a system. They excel in applications where speed and accuracy are paramount. Here’s a closer look at the advantages of solenoid valves.

Precision and Speed: The Advantages of Solenoid Valves

Solenoid valves are favored for their precision and speed in controlling the flow of fluids or gases. They can open and close in milliseconds, making them ideal for applications that require rapid response times. Their electromagnetic operation ensures accuracy in regulating flow rates, which is crucial in systems where precise control is necessary, such as in automated manufacturing or HVAC systems.

One significant advantage of solenoid valves is their suitability for remote and automated control. They can be easily integrated into control systems, allowing operators to adjust valve positions without manual intervention. This not only increases efficiency but also reduces the potential for human error. Solenoid valves are indispensable in industries where precise automation is vital.

Reliability and Simplicity: The Appeal of Manual Pneumatic Valves

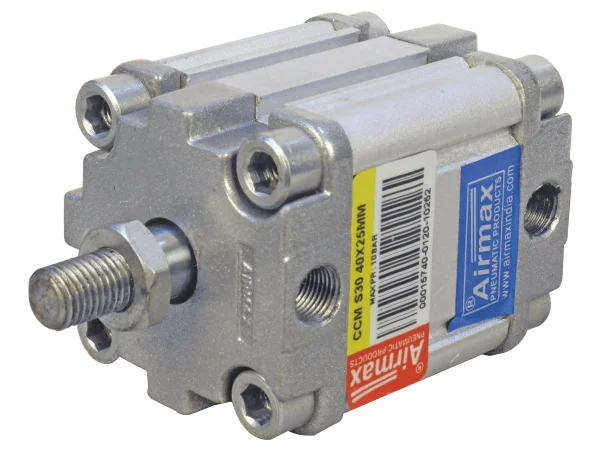

While solenoid valves excel in automation and precision, manual pneumatic valves have their own set of advantages. These valves are renowned for their reliability and simplicity. Manual valves are mechanically operated, often using levers or handwheels, which makes them robust and less prone to electrical failures.

Manual pneumatic valves are known for their ease of use and maintenance. Their straightforward design means that they are less complex and less likely to malfunction. This makes them a cost-effective choice for applications where basic on/off control is sufficient, such as in residential gas lines or simple industrial processes.

Pros and Cons of Solenoid Valves in Pneumatic Systems

Solenoid valves, despite their numerous advantages, also come with some drawbacks. They tend to be more expensive than manual pneumatic valves due to their electromechanical components. Additionally, solenoid valves rely on electrical power, which can be a disadvantage in environments where electrical disruptions are common.

Solenoid valves may not be the best choice for applications requiring high flow rates or in situations where power efficiency is a primary concern. In such cases, manual pneumatic valves, which can handle higher flow rates without the need for constant power, may be more suitable.

Choosing the Right Valve: Factors for Consideration

Selecting the appropriate pneumatic valve is crucial for optimizing system performance. Several factors should guide your decision. These include the required flow rate, pressure compatibility, material suitability, and environmental conditions. Whether it’s a solenoid or manual pneumatic valve, understanding your control needs is vital. Additionally, consider maintenance requirements and cost-effectiveness. By carefully evaluating these factors, you can ensure that the chosen pneumatic valve aligns with your specific system requirements, delivering efficiency and reliability.

In conclusion, the choice between solenoid valves and manual pneumatic valves depends on the specific requirements of your pneumatic system. Solenoid valves offer precision and rapid response, making them ideal for automated applications. On the other hand, manual pneumatic valves are valued for their reliability and simplicity. Careful consideration of the pros and cons of each type of valve is essential when designing or maintaining pneumatic systems to ensure the best performance and cost-effectiveness for your needs.