The Guide to 5/2 Direction Control Valves provides an accessible introduction to this fundamental component in fluid control systems. Explaining the basics, it covers the valve’s 5 ports and 2 positions, guiding readers through its operation and practical applications. With clear language and illustrative examples, beginners can grasp how these valves regulate airflow in pneumatic systems, making it an ideal starting point for understanding essential industrial equipment.

Understanding the Basics:

In the world of fluid control systems, 5/2 Direction Control Valves stand as vital components, orchestrating the precise movement of fluids and gases. To comprehend their significance, let’s delve into the key features and components that define these valves.

At a glance, the numerical designation “5/2” hints at the valve’s structure. It signifies the number of ports and positions the valve possesses. These valves have five ports, which serve as connection points for fluids, and two positions, indicating the two distinct flow paths the valve can establish.

The five ports are often labeled as follows: Pressure Inlet (P), Cylinder Ports (A and B), Exhaust (EA and EB). These ports are strategically placed to enable controlled fluid movement between different parts of a pneumatic system.

Valve Operation : Unraveling the Switching Process

Understanding how 5/2 Direction Control Valves transition between their two positions is fundamental. The operation of these valves involves two solenoids, which are electromechanical devices that control fluid flow. The two positions are often referred to as “normal” and “actuated.”

In the normal position, one solenoid is energized, while the other is de-energized. This directs fluid flow through one set of paths. When the valve is actuated, the energized solenoid switches, causing the fluid flow to redirect through the other set of paths. This switching process is achieved through the movement of internal mechanisms, allowing the valve to control the flow direction with precision.

Applications Across Industries:

The versatile nature of 5/2 Direction Control Valves makes them indispensable in various industries. From manufacturing and automation to automotive and aerospace, these valves facilitate tasks such as controlling robotic movements, actuating machinery, and managing fluid-driven processes.

In manufacturing, they regulate the movement of pneumatic cylinders and robotic arms, ensuring precise positioning and efficient assembly. In the automotive sector, these valves control air pressure in pneumatic systems that operate brakes and clutches. Even in the medical field, they find use in controlling air pressure in medical devices.

Installation and Maintenance:

Correct installation and maintenance are pivotal for the effective performance and longevity of 5/2 Direction Control Valves. During installation, ensure proper alignment and connection of ports to prevent leaks and inefficiencies. Regular maintenance involves inspecting for wear, cleaning components, and addressing any issues promptly.

Troubleshooting Common Issues:

Despite their reliability, 5/2 Direction Control Valves can encounter common problems. Issues like leaking seals, blocked passages, or malfunctioning solenoids can disrupt their functionality. To address these concerns, it’s crucial to diagnose the problem accurately. This can involve checking electrical connections, inspecting seals, and ensuring proper lubrication.

Conclusion :

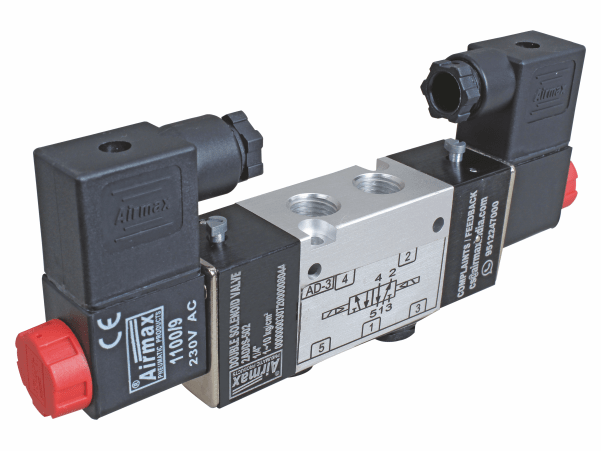

In conclusion, the world of fluid control owes a significant debt to the simplicity and effectiveness of 5/2 Direction Control Valves. With a grasp of their key features, operational mechanisms, and applications, individuals can navigate their usage across diverse industries. Proper installation, maintenance, and troubleshooting practices further ensure that these valves continue to facilitate seamless fluid control and enable efficient processes. Airmax Pneumatic offers advanced 5/2 Direction Control Valves, pivotal components in fluid control systems. With precision engineering, these valves seamlessly switch between two positions, driving efficient pneumatic operations across industries. Trust us for reliable solutions in fluid dynamics.