As an inspiration engineer with the trip of selecting coil air valves for your new machine, their square measure varied fascinating points: what port size do I need? what voltage? singular valves or on a complex? I patterned I’d share this important pneumatic framework configuration tip to protect people around your machine.

Anyway, however, would you decide once eudaemonia motivations need to utilize a double coil instead of one solenoid? however regarding we tend 1st separate the contrasts between these varieties of valves.

Single and Double Coil Air solenoid Valve variations

You need to maneuver a heap with a pneumatic actuator which might either be an immediate air chamber or a pneumatic rotational actuator. the two} sorts have 2 ports and placing pressure into either move. The air chamber can either expand or withdraw contrasted and also the rotational actuator which will flip clockwise or counterclockwise.

Most pneumatic applications need a typical 4-way, five-ported directional air valve to manage these double acting pneumatic actuators. For this purpose, once the spool during this type of valve is enraptured, it sends strain to either actuator port fittings relying upon the position. The strategy makes the spool move that separates one from a double coil valve.

Single Coil solenoid Valves

If your valve may be a single coil kind, it implies once the voltage is applied to the one “A” solenoid coil, the first spool within the valve can move which can cause the valve ports to yield air on one facet creating the pneumatic actuator reach dead set another position. At the purpose, once force is eliminated, the first spool can naturally retreat to the primary position in lightweight of the fact that an inward spring or air is compelling it back. This moves the air yield to future port confining the actuator to urge back to its distinctive position.

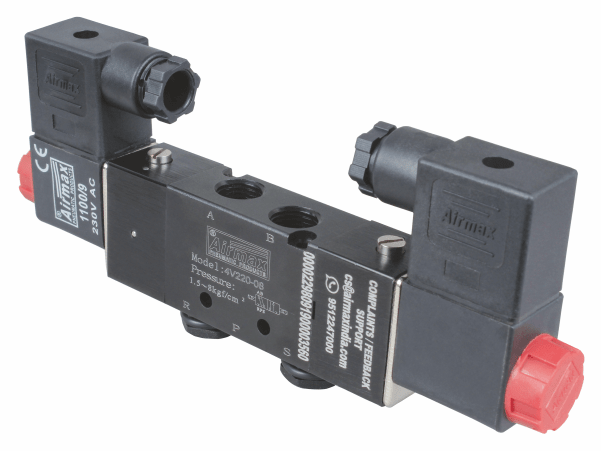

Double Coil solenoid Valves

On the off probability that the valve may be a double coil solenoid valve type, once a voltage is applied to the “A” solenoid coil, an analogous can occur as higher than. the elemental spool within can move aside allowing air to stream to broaden the actuator. At the purpose, once force is taken out from the “A” coil, this point the principle spool can keep equally set with a pawl. No movement of the air mechanism can happen. The spool can presumably move if power is applied to the “B” solenoid coil, this valve has a pair of solenoids, that is that the manner it gets its name double solenoid. to revive the actuator to its distinctive position, you must invigorate the second “B” coil. this may move the spool back and cause air to stream out the opposite port, giving strain to the mechanism to withdraw back.

Presently therewith knowledge, you wish to require a goose at every pneumatic actuator on your new machine and raise yourself-“What may occur if the machine lost electrical force?”